MIM is the appropriate technology for manufacturing components with complex geometries and in a large variety of different metallic materials.

MIM is the appropriate technology for manufacturing components with complex geometries and in a large variety of different metallic materials.

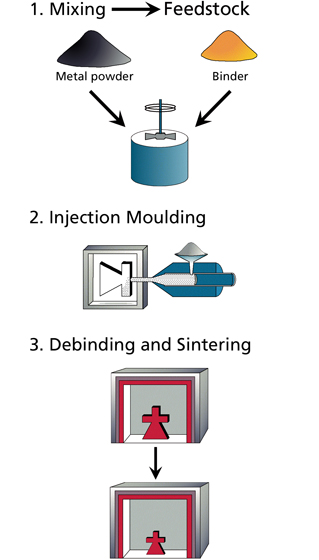

Metal powders are compounded together with an organic binder to form a feedstock. These homogeneous granulates provide thermoplastic properties and can be injected into the cavity of a MIM-press under temperature.

Parts which are produced by MIM are already near-net-shaped. The organic binder is removed so that upon sintering the parts have excellent surface properties be removed (“debound”) and after the sintering the parts have a high quality of surface. Precise moulds are essential to guarantee for achieving the required tight tolerances. Further finishig processes can be added in certain cases but are not necessary for most of the applications.

The MIM-Technology is a very efficient shaping process for large quantities and complex, three-dimensional geometries and provides the major advances:

1. Capabilities

2. Advanced material properties

3. Premium surface quality

4. Tight tolerances

5. Broad selection of material grades

6. Ideal utilization of used raw materials